Galvanisation

A good electroplated coating determines the service life of metal parts. It protects against corrosion, improves electrical properties and can make products more suitable for assembly, soldering or intensive use. At Galvano Hengelo, we combine modern installations with craftsmanship, so that every treatment does exactly what you need it to do.

Galvanisation is a reliable way to protect parts durably and ensure consistent performance.

Why choose Galvano Hengelo?

- Quality always comes first

- Largest electroplating production line in the Netherlands

- More than 25 years of experience

- ISO 9001 and ISO 14001 certified

- Average delivery time of 3 to 5 working days

- Option for a fully comprehensive service, including packaging, labeling and sorting

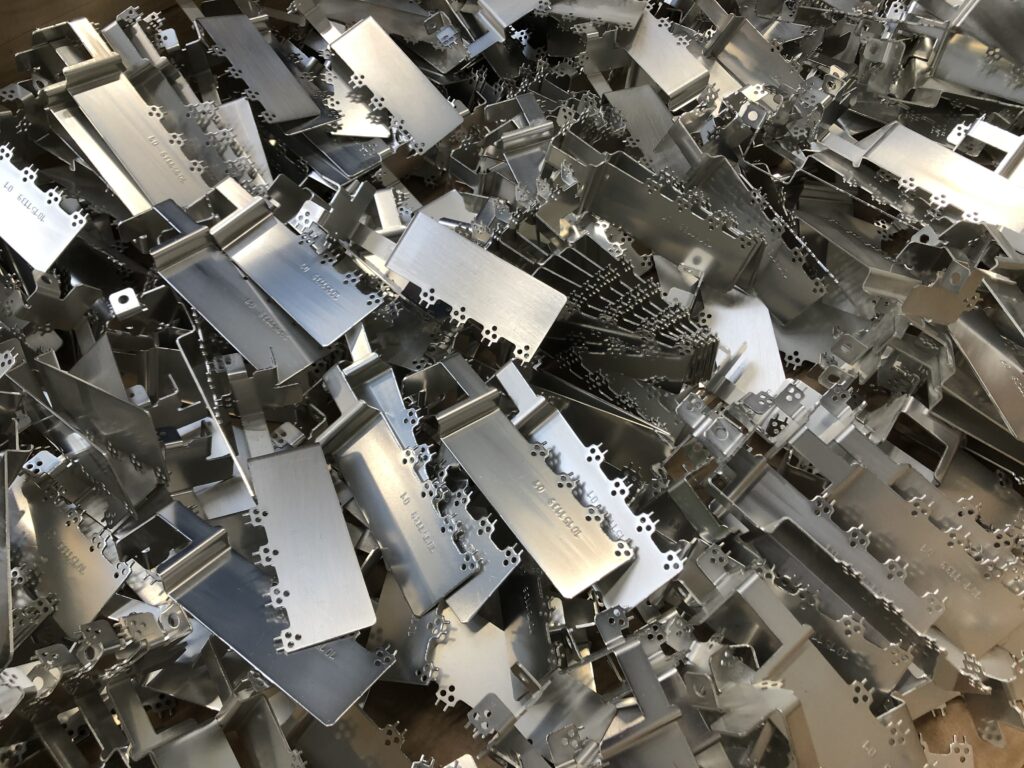

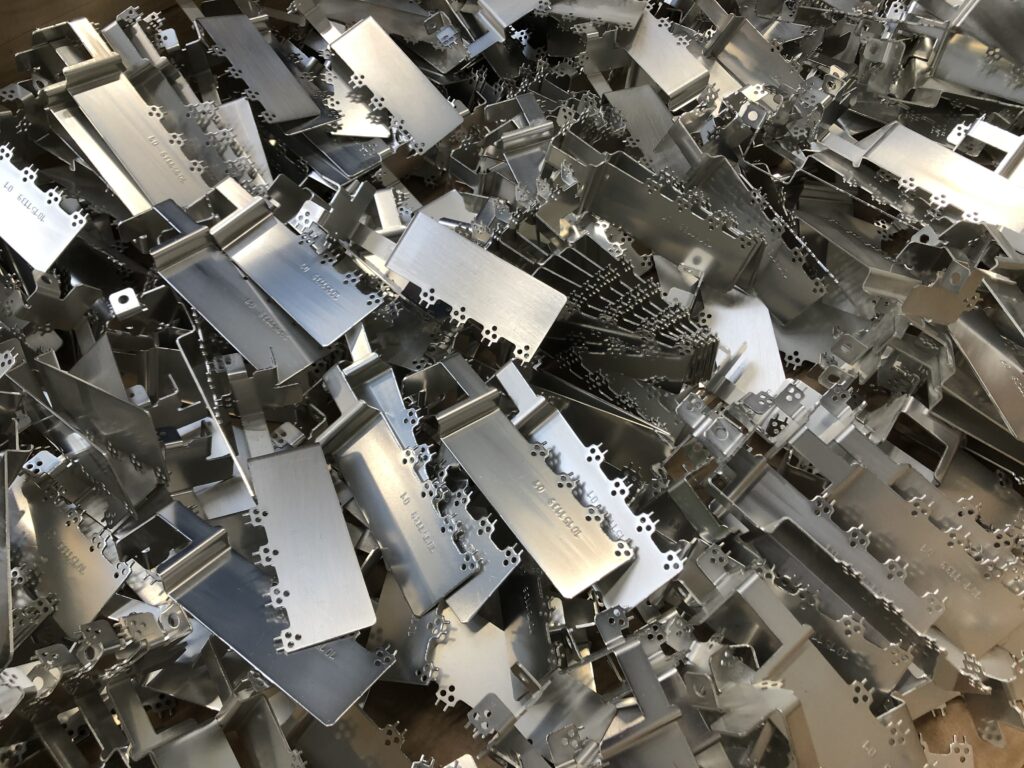

Our galvanisation techniques

We offer a wide range of galvanisation and chemical surface treatments. Together, we determine which treatment best suits your desired product properties, such as corrosion resistance, conductivity, hardness, or solderability.

Silver plating

Silver provides extremely low resistance and therefore excellent electrical conductivity. It is therefore a logical choice for conductors, contacts and connections in electrical engineering.

Examples:

- Current conductors

- Switch contacts

- Conductor bushings

Tinning

Tin improves solderability and protects against corrosion. It also remains ductile. This treatment is often used in the food, electrical and electronics sectors.

Examples:

- Battery terminals

- Current conductors

- Contacts and components

Protalloy® (zinc-nickel coating)

Our optimised zinc-nickel coating is known for its high corrosion resistance and long service life. The coating performs particularly well in conditions of high humidity, salt exposure and fluctuating temperatures. Protalloy® also forms a good adhesive layer for any paint finish.

Examples:

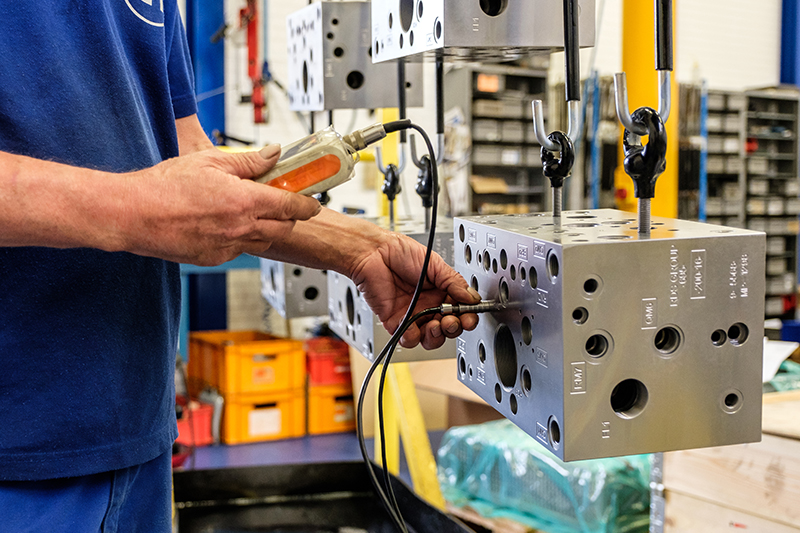

- Manifolds

- Construction parts

- Tow bars

Chemical nickel plating

Although chemical nickel plating is not electrolytic, in practice it is considered to be a galvanic treatment. It produces a very even and dimensionally stable layer (approximately ± 2 µm tolerance on the applied layer thickness). This treatment is suitable for parts that require extra protection or where uniformity and hardness are important.

The standard hardness is approximately 600 HV and with heat treatment this can increase to 900 to 1000 HV. Cavities and holes are evenly coated.

Examples:

- Gears

- Hose couplings

- Telecom test equipment

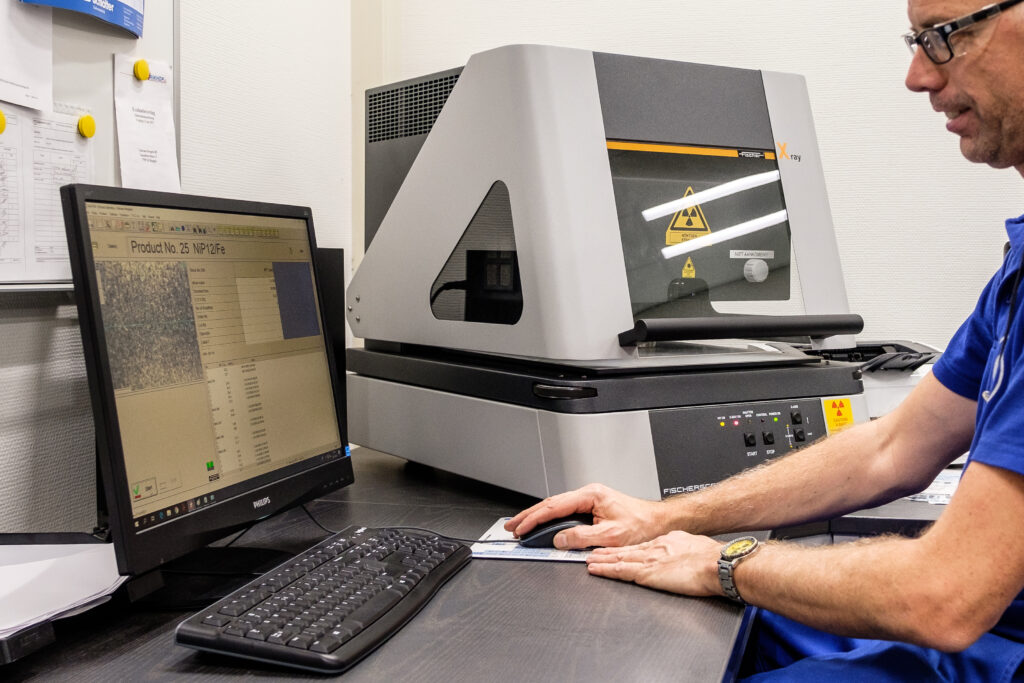

Quality from our own laboratory

Our own laboratory specialists continuously monitor the baths and processes. This ensures that every batch meets the highest standards and that the properties are consistent.

The real advantages of galvanising

The advantages listed below apply to galvanising in general, i.e. the application of a protective metal coating. Specific properties may vary depending on the treatment.

- Better corrosion protection

The metal coating acts as a shield against rust and environmental influences, extending the service life of components.

- Consistent coating thickness

Galvanic processes make it possible to apply thin and even layers without significantly affecting tolerances.

- Better functionality

The protective layer prevents wear and tear and makes parts less susceptible to damage, which helps prevent malfunctions.

- Additional properties

These include conductivity, solderability and hardness. These properties depend on the treatment chosen.

Toepassingen in verschillende sectoren

We galvanise components for a wide range of industries, including:

- Electrical engineering and electronics

- Hydraulic drive technology and automotive

- Defence and aviation

The combination of precision, high quality and short delivery times makes Galvano Hengelo suitable for applications where reliability is essential.

What is galvanisation?

Galvanisation is a process in which a metal component is coated with a thin layer of metal. In an electrolytic treatment, the product acts as a cathode and the coating material dissolves from the anode into the bath.

The metal ions then adhere to the product surface. In chemical nickel plating, this occurs without electricity and chemistry is the driving factor behind the process. The result is a durable, protective and functional layer.

Have your product galvanised

Would you like to improve the conductivity of parts, protect them against corrosion or make them more wear-resistant? At Galvano Hengelo, we work with you to select the right treatment and deliver quickly and accurately according to your specifications.

- Average delivery within 3–5 working days

(24- and 48-hour service available) - ISO 9001/14001 certified

- More than 25 years of experience