Our treatments

Do you want to make your product more conductive or protect it from corrosion? With the right surface treatment, you improve the performance and service life of your parts.

Depending on the application, we offer various metal coatings that improve conductivity, wear resistance or corrosion resistance, among other things.

Why choose Galvano Hengelo?

- Average delivery within 3 – 5 working days

(24- and 48-hour service possible) - ISO 9001/14001 certified

- More than 25 years of experience

Possible surface treatments

Silver electroplating

- Strong improvement of current flow

- On copper and aluminium

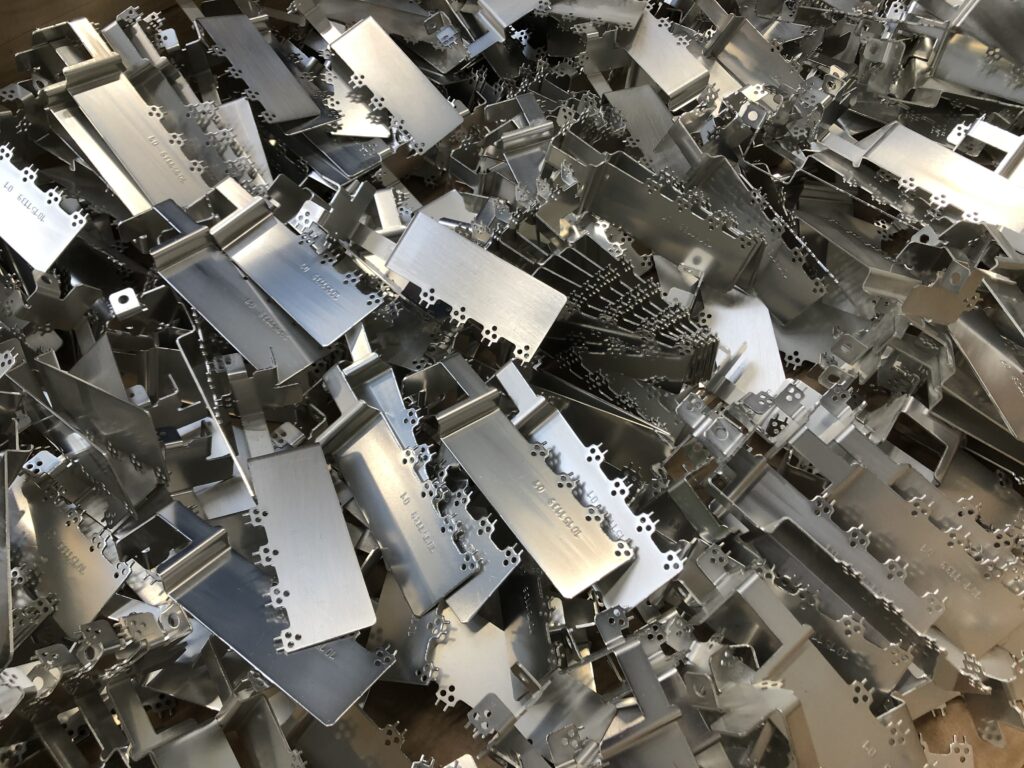

- Barrel plating, rack plating

Tin electroplating

- Improves solderability and corrosion resistance

- On copper, brass, aluminium and steel

- Barrel plating, rack plating

Protalloy® (Zinc-nickel electroplating)

- At least 1,500 hours of corrosion protection (NSS)

- On steel and cast iron

- Partial zinc-nickel possible

- Barrel plating

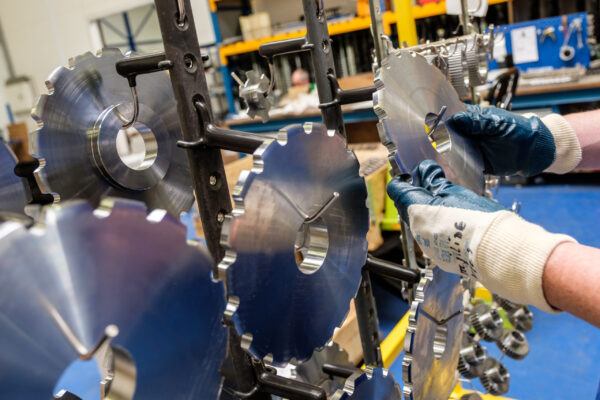

Electroless nickel plating

- Corrosion protection and preservation

- On steel and cast iron (depending on porosity)

- Surface hardness up to 1000 HV possible

- Coating thickness tolerances up to ± 2μm

- Barrel plating

Customer stories

“For our winch parts in saltwater environments, we needed reliable corrosion protection. With Protalloy® from Galvano Hengelo, we found a durable zinc-nickel treatment that protects our parts and makes them look beautiful.”

“We were looking for durable protection for heavily loaded parts. Electrogalvanising did not hold up, so we chose Protalloy® from Galvano Hengelo. This zinc-nickel treatment is wear-resistant, rust-proof and much more efficient for our process.”

What is a galvanic surface treatment?

Galvanic surface treatment is a treatment in which we apply a metallic coating to a metallic substrate.

Metal surface treatment

We have a specific solution for every surface. The purpose of the surface treatment determines the type of treatment we recommend and perform for you. We carry out surface treatments on substrates such as:

- Copper

- Aluminium

- Brass

- Steel

- Cast Iron

We have a specific solution for each surface. The purpose of the surface treatment determines the type of treatment we recommend and perform for you. The result: a product that meets your needs and requirements.

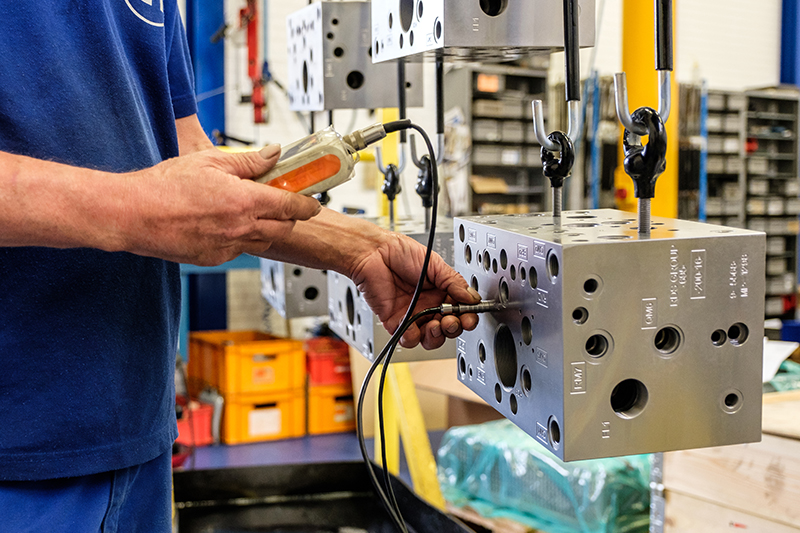

The right treatment for your product

To determine which treatment is most suitable, we will discuss the process with you beforehand. Questions such as what the product will be used for, whether it will be exposed to wear and tear, and what its main purpose is, are essential questions to answer.

We apply the right metal layer to your product or semi-finished product by using modern and automated production lines. We have been specialists in electroplating and various surface treatments for years, each with their specific applications and benefits.

Thanks to our many years of experience, we have optimized our processes, and know exactly what the best possible treatment for your product is. We also have the expertise in-house to advise you as best as possible based on your preferences and requirements.