Galvano Hengelo

Improving the properties of your product or semi-finished product through surface treatment is our expertise. With an average delivery time of 3-5 days, we can always serve you quickly and in an extremely professional manner.

Customers currently rate us with a 8,3

Your Specialist in Galvanizing

Does your product or semi-finished product need to be well protected against corrosion? Or does it need to perform better in terms of wear resistance, solderability, or electrical conductivity? Welcome to Galvano Hengelo, specialist in galvanizing for the supply industry.

We specialize in applying metallic coatings to metallic substrates. Our added value? The high quality of our surface treatments, short delivery times, clear communication, and continuous focus on improvement. Galvano Hengelo is ISO9001 and ISO14001 certified.

Our surface treatments

Silver electroplating

Specialized in improving components by applying a galvanic silver coating to copper, aluminum, and steel, which enhances corrosion resistance, electrical conductivity, and wear resistance.

Tin electroplating

We can apply a tin coating to copper alloys, aluminum, and steel, providing good solderability, ductility, and corrosion protection.

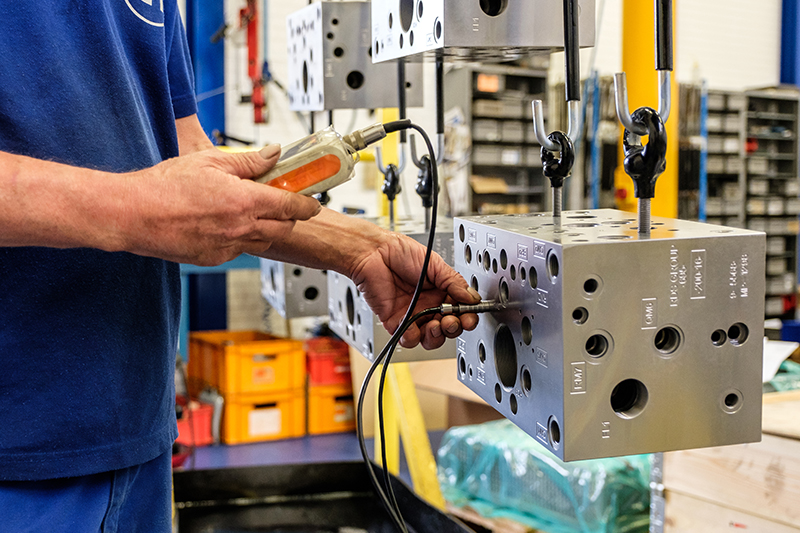

Chemical Nickel Plating

Chemical Nickel Plating provides an even and highly uniform coating across the entire product. Complex products that are difficult to galvanize or products with ± 2 microns are highly suitable for chemical nickel plating.

Protalloy®

Protalloy®, also known as zinc-nickel plating, is our proprietary surface treatment with superior corrosion-resistant properties. We guarantee 1500 hours of corrosion protection according to the Neutral Salt Spray Test.

We galvanise among others for

Quick

Delivery typically within 3 – 5 working days

24-hour and 48-hour service available

Quality

- More than 25 years of experience

- ISO 9001 / ISO 14001

- In-house laboratory

Service

Tailored advice

Inspection

Packaging & labeling

Taking care of

We work extensively for the following markets

Electrical engineering

For good electrical conductivity, silver plating of components plays an important role. It is crucial that the products we silver plate are able to conduct electricity optimally and over a long period of time.

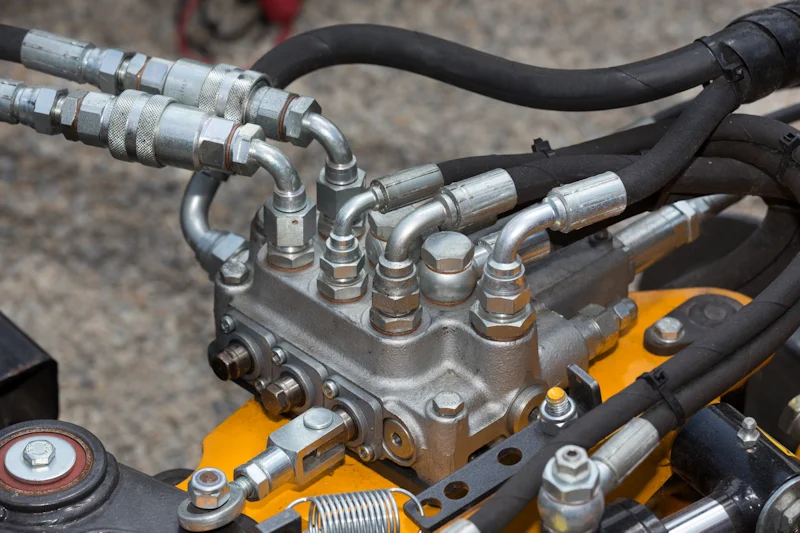

Hydraulic

Protalloy® is designed in such a way that internal rust in channels, product damage, and dimensional issues in hydraulic components do not occur. Corrosion protection of at least 1500 hours NSS (Neutral Salt Spray Test).

Defence and aerospace

Galvano Hengelo offers high-quality surface treatments for defense and aerospace. We process semi-finished products for various components used in radar equipment, armored vehicles, and much more.

Automotive

We process various automotive components such as battery terminals, tow hooks, transmission parts, shock absorbers, and charging connector contacts with various surface treatments.

Agriculture

Galvano Hengelo processes components of tractors and agricultural machines with a zinc-nickel coating for enhanced protection and durability.

About Galvano Hengelo

Galvano Hengelo is a specialized galvanizing company, founded in 1996. We distinguish ourselves with high-quality surface treatments for a broad and stable customer base. We provide galvanizing services for all of Western Europe.

You can rely on us for trusted solutions, and we continuously strive for innovation and custom-made solutions in the field of galvanizing.

Sustainability as a Guideline

Our entire process is focused on sustainability and minimizing environmental impact. Your products have a much longer lifespan due to the coatings we apply. Additionally, our environmental policy is aimed at monitoring, controlling, and continuously reducing the impact of our processes on the environment wherever possible.

We achieve this by using state-of-the-art techniques and continuously optimizing our processes, so we minimize the environmental burden while delivering the highest possible quality.